Machine learning for the characterization and design of battery electrodes

Machine learning for the characterization and design of battery electrodes

Abstract

Battery companies want to know the relationship between their manufacturing parameters and the performance of the resulting cells, so that they can optimize their products for particular applications, reduce costs, and improve yield. The literature contains many examples of physics-based models of the various manufacturing processes (including mixing, coating, drying and calendaring), but these systems are hugely complex, and as a result they are expensive to simulate and hard to validate.

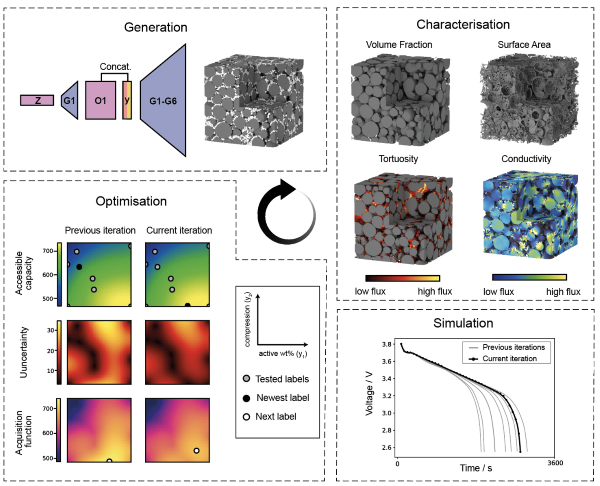

Recent advances in generative machine learning (ML) methods have allowed the relationship from manufacturing parameters to microstructure to be directly learned from data.

In this talk I will present a modular approach to the cell optimization cycle that makes use of these ML methods, in combination with GPU accelerated metric extraction (TauFactor 2), electrochemical cell simulation (PyBaMM), and Bayesian optimization. In addition, I will be introducing a new kintsugi SEM imaging method for accurately observing the nanostructure of the carbon binder domain; “VoxCel” an open-source, voxel-based, GPU-accelerated, multi-physics cell simulation; ML methods for generating 3D data from 2D images, as well as, inpainting artefacts in image data; and a data fusion method for combining multi-modal datasets using GANs. Lastly, I’ll present a webapp that normalizes the data obtained from testing cells in a lab for easy comparison to commercial cells: cell-normaliser

Speaker

Dr. Samuel J. CooperDr Sam Cooper is a Senior Lecturer in the Design of Energy Materials at Imperial College London. His team develop open-source machine learning and simulation tools for the characterisation and optimisation of energy storage devices. https://tldr-group.github.io. He has also recently spun-out a company focused on the optimization of lithium-ion battery electrodes use AI: https://www.polaron.ai